The knock sensor plays a crucial role in modern automotive engines. It is designed to detect engine knocking or pinging, a phenomenon that can lead to significant engine damage if left unchecked. By accurately identifying the presence of abnormal combustion, the knock sensor allows the engine control unit (ECU) to adjust the ignition timing, ensuring smooth and efficient engine operation. This tiny yet powerful component helps maintain optimal engine performance, minimizes emissions, and enhances fuel efficiency, making it an essential part of today’s vehicles.

Knock sensors have become a staple in the automotive industry due to their ability to safeguard engines from potential harm. Engine knocking, often caused by improper combustion timing, can result in a loss of power and increased wear and tear on the engine components. The knock sensor serves as a protective measure, alerting the ECU to make necessary adjustments and prevent damage. Its function is vital in ensuring the longevity and reliability of an engine, which is why it is integrated into almost every modern vehicle.

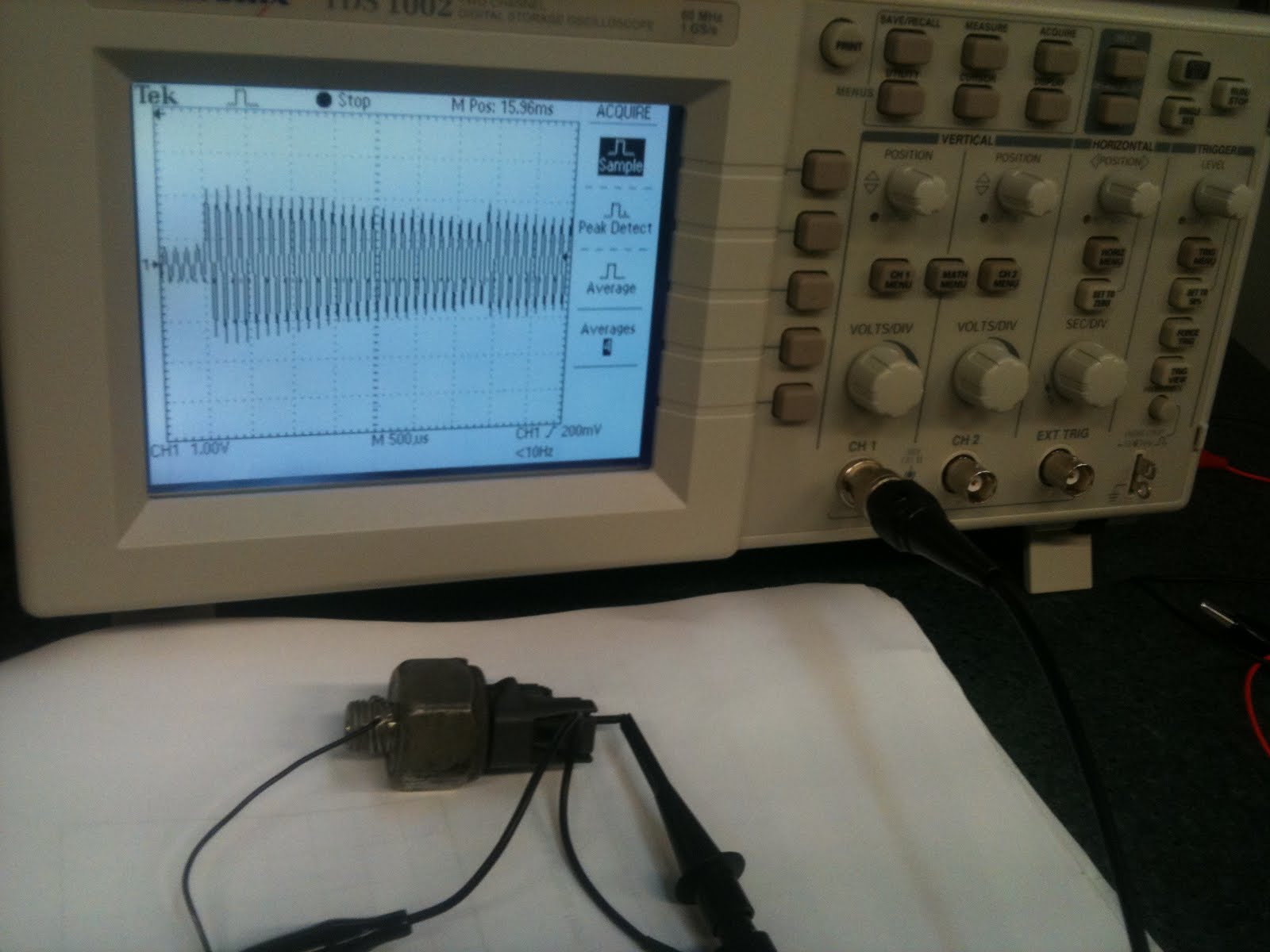

With advancements in technology, knock sensors have evolved to become more sensitive and precise in detecting engine knocking. They are typically made from piezoelectric materials that generate a voltage when subjected to vibrations. This voltage signal is then interpreted by the ECU to adjust the engine's parameters accordingly. Understanding how a knock sensor works, its importance, and how to troubleshoot common issues can help vehicle owners and mechanics ensure the optimal performance and efficiency of their vehicles.

Read also:Naked Men Insightful Perspectives And Societal Impacts

Table of Contents

- What is a Knock Sensor?

- How Does a Knock Sensor Work?

- Importance of Knock Sensors in Modern Engines

- Common Symptoms of Knock Sensor Failure

- How to Troubleshoot Knock Sensor Issues?

- Can a Faulty Knock Sensor Affect Engine Performance?

- Steps to Replace a Faulty Knock Sensor

- Tips for Maintaining Your Knock Sensor

- Different Types of Knock Sensors

- How to Choose the Right Knock Sensor?

- Frequently Asked Questions

- Conclusion

What is a Knock Sensor?

A knock sensor is an electronic component that detects engine knocking, also known as pinging, caused by premature combustion of the air-fuel mixture in an engine cylinder. This sensor is typically mounted on the engine block, cylinder head, or intake manifold. Its primary role is to monitor engine vibrations and sound frequencies that indicate abnormal combustion, sending signals to the engine control unit (ECU) to adjust the ignition timing as needed.

Engine knocking is a critical issue as it can cause significant damage if not addressed. The knock sensor helps prevent this by ensuring the engine operates within safe parameters. It’s a vital part of the engine management system, providing real-time feedback to maintain optimal engine performance.

How Does a Knock Sensor Work?

The knock sensor operates by utilizing piezoelectric materials that produce a voltage when subjected to mechanical stress, such as engine vibrations. When the knock sensor detects knocking, it generates a voltage signal proportional to the intensity of the knock. This signal is then transmitted to the ECU, which interprets it and adjusts the ignition timing to prevent premature detonation.

The ECU uses this information to delay the spark timing, reducing the likelihood of knocking and ensuring smoother engine operation. By constantly monitoring and adjusting the engine parameters, the knock sensor helps to optimize fuel efficiency and minimize emissions. This ongoing adjustment process is crucial for the longevity and reliability of the engine.

Importance of Knock Sensors in Modern Engines

Knock sensors are integral to modern engines, playing a significant role in maintaining engine health and performance. They help prevent engine damage by detecting knocking early and allowing the ECU to make necessary adjustments. As such, they contribute to improved fuel efficiency, reduced emissions, and extended engine life.

In modern engines, which are designed to operate with higher compression ratios and advanced ignition systems, the knock sensor is even more critical. It ensures that engines can run efficiently without succumbing to the adverse effects of knocking. This is particularly important as manufacturers strive to meet stricter emissions and fuel economy standards.

Read also:Asian Massage Parlor A Relaxing Retreat And Cultural Experience

Common Symptoms of Knock Sensor Failure

When a knock sensor fails, it can lead to a range of engine performance issues. Recognizing these symptoms can help in diagnosing and addressing the problem promptly. Common signs of a faulty knock sensor include:

- Check Engine Light: One of the most obvious indicators is the illumination of the check engine light on the dashboard.

- Reduced Engine Performance: A failing knock sensor can cause a noticeable loss in engine power and acceleration.

- Poor Fuel Economy: The engine may consume more fuel than usual, as it cannot optimize ignition timing effectively.

- Increased Emissions: Without proper ignition timing adjustments, emissions may increase, leading to potential environmental concerns.

- Engine Noise: In some cases, unusual engine noises or knocking sounds may be audible.

How to Troubleshoot Knock Sensor Issues?

Troubleshooting a knock sensor involves several steps to determine whether the sensor is faulty or if there’s another underlying issue. Here’s a step-by-step guide to help identify and resolve knock sensor problems:

- Scan for Error Codes: Use an OBD-II scanner to check for diagnostic trouble codes related to the knock sensor.

- Inspect Sensor and Wiring: Visually inspect the knock sensor and its wiring for any signs of damage or corrosion.

- Test Sensor Voltage: Use a multimeter to test the voltage output of the knock sensor. Compare it with the manufacturer’s specifications.

- Check for Engine Knocking: Listen for any knocking or pinging sounds that may indicate sensor failure.

- Consult a Professional: If the issue persists, it may be necessary to consult a professional mechanic for further diagnosis and repair.

Can a Faulty Knock Sensor Affect Engine Performance?

Yes, a faulty knock sensor can significantly impact engine performance. When the sensor fails to detect knocking accurately, the ECU cannot adjust the ignition timing properly. This can lead to several issues, including:

- Loss of Power: The engine may not perform optimally, resulting in reduced acceleration and power output.

- Increased Fuel Consumption: Without proper timing adjustments, the engine may burn more fuel, lowering fuel efficiency.

- Higher Emissions: Inefficient combustion due to incorrect timing can increase harmful emissions.

- Potential Engine Damage: Prolonged knocking can cause damage to engine components, leading to costly repairs.

Steps to Replace a Faulty Knock Sensor

Replacing a faulty knock sensor requires some technical knowledge and tools. If you’re confident in your mechanical skills, follow these steps to replace the knock sensor:

- Disconnect the Battery: Ensure safety by disconnecting the vehicle's battery to prevent electrical shocks.

- Locate the Knock Sensor: Refer to the vehicle's service manual to find the exact location of the knock sensor.

- Remove the Old Sensor: Carefully disconnect the wiring harness and unscrew the faulty sensor from its mounting point.

- Install the New Sensor: Place the new knock sensor in the correct position and secure it by screwing it in place.

- Reconnect the Wiring: Attach the wiring harness to the new sensor and ensure it is connected securely.

- Test the Installation: Reconnect the battery and start the engine to verify that the new sensor is functioning correctly.

Tips for Maintaining Your Knock Sensor

Proper maintenance of the knock sensor can help prolong its lifespan and ensure it functions effectively. Here are some tips to keep your knock sensor in good condition:

- Regular Inspections: Periodically check the sensor and its wiring for any signs of wear or damage.

- Clean Connections: Ensure that the electrical connections are clean and free of corrosion to maintain optimal signal transmission.

- Avoid Engine Overheating: Overheating can damage the knock sensor, so ensure the cooling system is functioning properly.

- Use Quality Fuel: Using high-quality fuel can reduce the likelihood of engine knocking and improve sensor performance.

Different Types of Knock Sensors

There are several types of knock sensors, each with unique characteristics and applications. Understanding these differences can help in selecting the right sensor for your vehicle:

- Resonant Type: This sensor is tuned to a specific frequency and is ideal for detecting engine knocks within a narrow frequency range.

- Wideband Type: Capable of detecting a broader range of frequencies, this sensor is more versatile and suitable for modern engines.

- Piezoelectric Type: Known for its accuracy, this sensor uses piezoelectric materials to generate voltage signals in response to engine vibrations.

How to Choose the Right Knock Sensor?

Choosing the right knock sensor for your vehicle is crucial for optimal performance and reliability. Consider the following factors when selecting a knock sensor:

- Compatibility: Ensure the sensor is compatible with your vehicle's make, model, and engine specifications.

- Type: Choose between resonant, wideband, or piezoelectric sensors based on your engine's requirements.

- Quality: Opt for high-quality sensors from reputable manufacturers to ensure durability and reliability.

- Price: While cost is a factor, prioritize quality over price to avoid potential issues down the line.

Frequently Asked Questions

What happens if I ignore a faulty knock sensor?

Ignoring a faulty knock sensor can lead to severe engine damage due to uncontrolled knocking. Over time, this can result in costly repairs and decreased engine performance.

Can I drive with a bad knock sensor?

It is not recommended to drive with a faulty knock sensor, as it can lead to increased engine knocking, reduced performance, and potential engine damage.

How often should I replace my knock sensor?

Knock sensors typically last for many years, but it’s advisable to replace them as part of regular maintenance or if they exhibit signs of failure.

Can a knock sensor be cleaned?

While you can clean the connections of a knock sensor, cleaning the sensor itself is not recommended. If the sensor is faulty, it’s best to replace it.

Does a knock sensor affect fuel economy?

Yes, a functioning knock sensor helps to optimize fuel economy by allowing the ECU to adjust the ignition timing for efficient combustion.

Are knock sensor issues covered under warranty?

This depends on the vehicle manufacturer and warranty terms. Some warranties may cover knock sensor replacement if it fails within the warranty period.

Conclusion

The knock sensor is an essential component in modern engines, ensuring efficient operation and preventing potential damage due to engine knocking. By understanding its functionality, importance, and how to troubleshoot issues, vehicle owners can maintain optimal engine performance and longevity. Regular maintenance and prompt attention to symptoms of failure can help avoid costly repairs and ensure a smooth driving experience. Whether you’re a car enthusiast or a professional mechanic, knowledge of the knock sensor and its role in the engine management system is invaluable.

For more detailed information on automotive sensors and their applications, consider visiting Auto Service Professional, a reliable source for automotive technology insights.